Import Excel Heat Data into Nastran Efficiently

To efficiently import Excel heat data into Nastran, a popular finite element analysis (FEA) software, requires not only a clear understanding of both tools but also a strategy to streamline the data transfer. Whether you're an engineer, designer, or researcher, the process outlined below will ensure accuracy and efficiency in your FEA projects. Let's delve into the steps for seamless integration.

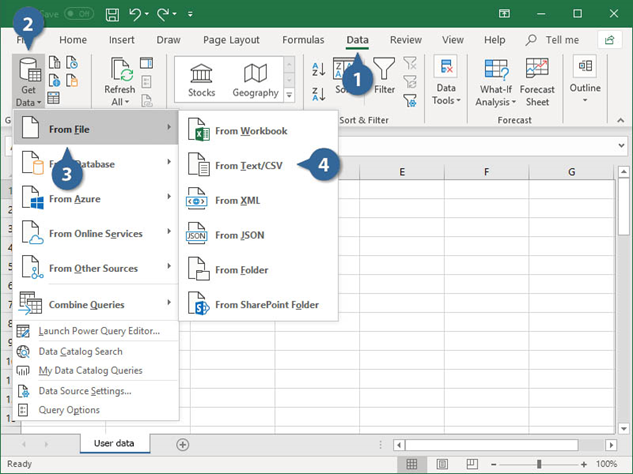

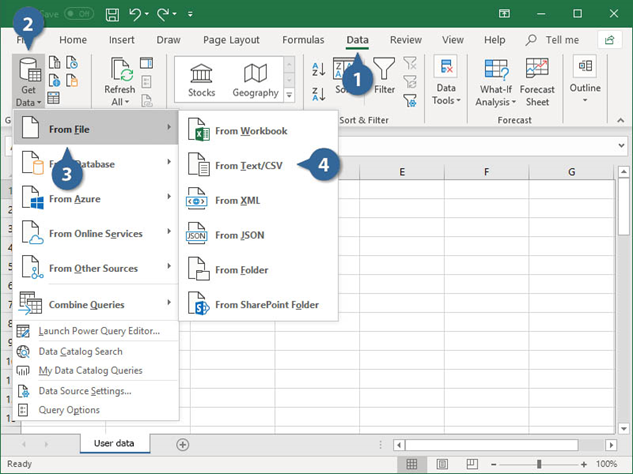

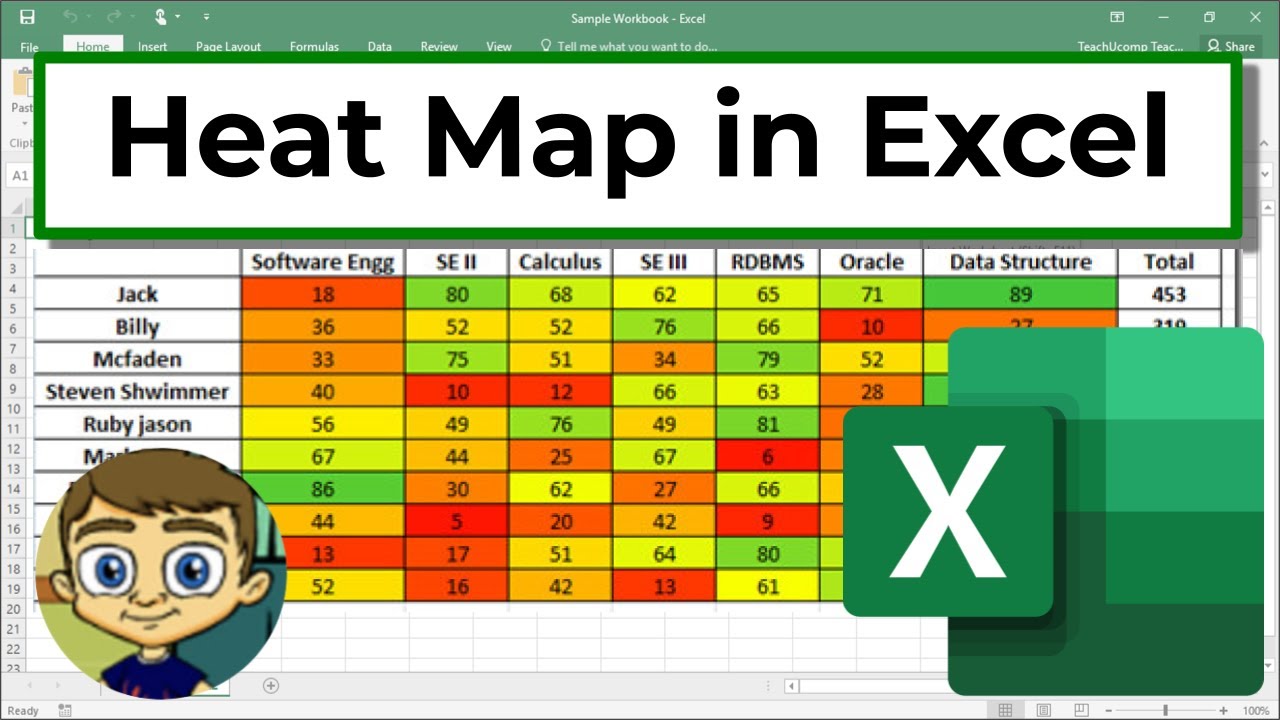

Preparation of Excel Data

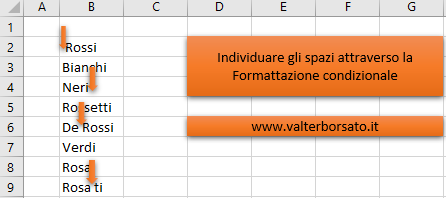

- Organize the Data: Ensure that your Excel file is structured with headers corresponding to Nastran fields such as Node ID, Temperature, etc.

- Data Consistency: Check for consistency in naming conventions, formats, and units to avoid errors during the import process.

- Conduct a Check: Validate the data through formulas or pre-processing tools to spot potential issues before export.

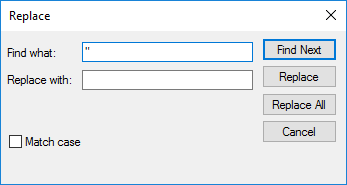

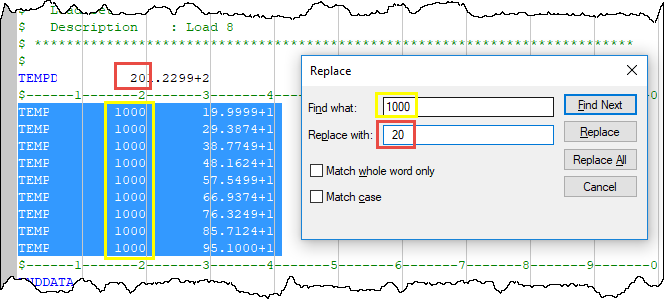

Conversion into Nastran Format

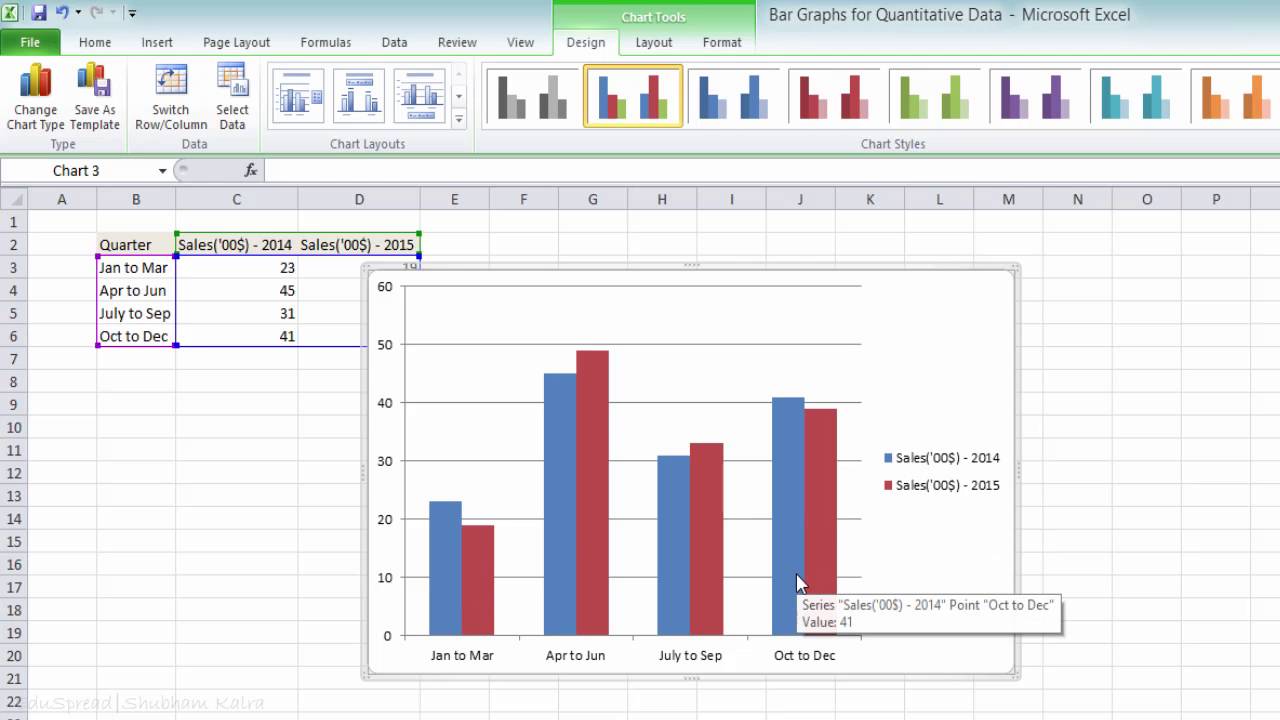

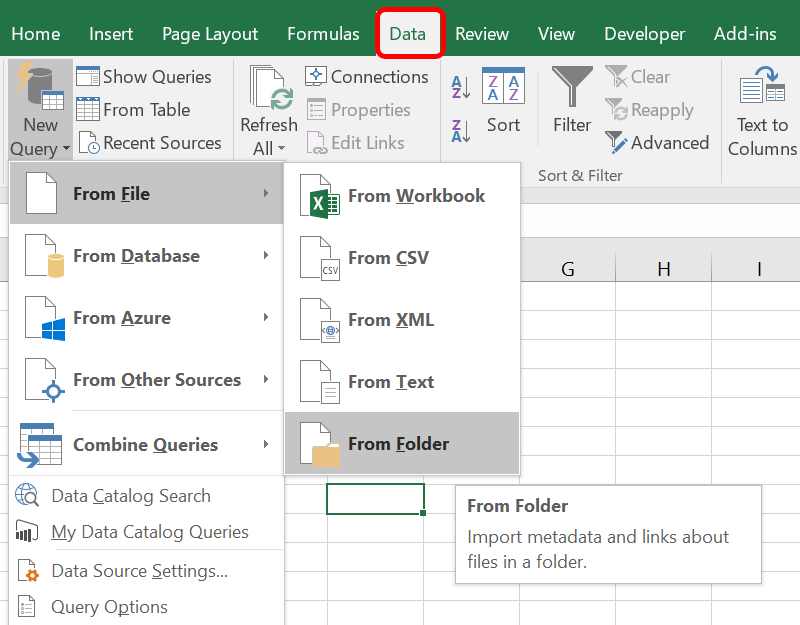

You can either manually write a script or use dedicated conversion tools to transform Excel data into Nastran Bulk Data Deck (BDF) or direct input formats:

- Using Python: Script your own conversion with libraries like Pandas for Excel reading and writing to a text file.

- Using Conversion Tools: Employ tools like HyperMesh or PATRAN to automate the conversion process.

| Conversion Method | Tools Required | Pros | Cons |

|---|---|---|---|

| Manual Scripting | Python, VBA | High customization, learning opportunity | Time-consuming, scripting knowledge required |

| Conversion Software | HyperMesh, PATRAN | Time-saving, less manual intervention | Software cost, dependency on third-party tools |

💡 Note: When scripting, consider adding logging or error handling for efficient troubleshooting.

Data Validation

Ensure the data imported into Nastran is accurate by:

- Loading the imported deck in Nastran for a preliminary check.

- Using Nastran commands like

TEMPDorQBDY1to verify thermal boundary conditions. - Checking the imported data visually or using Nastran’s diagnostic tools for consistency and correctness.

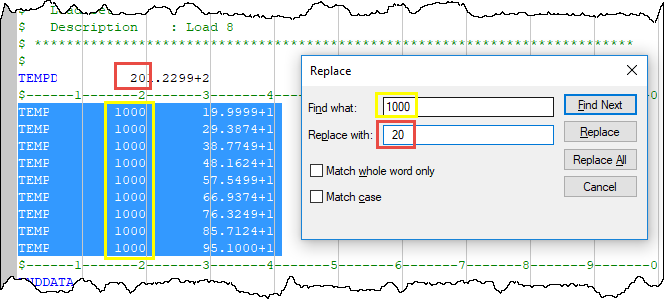

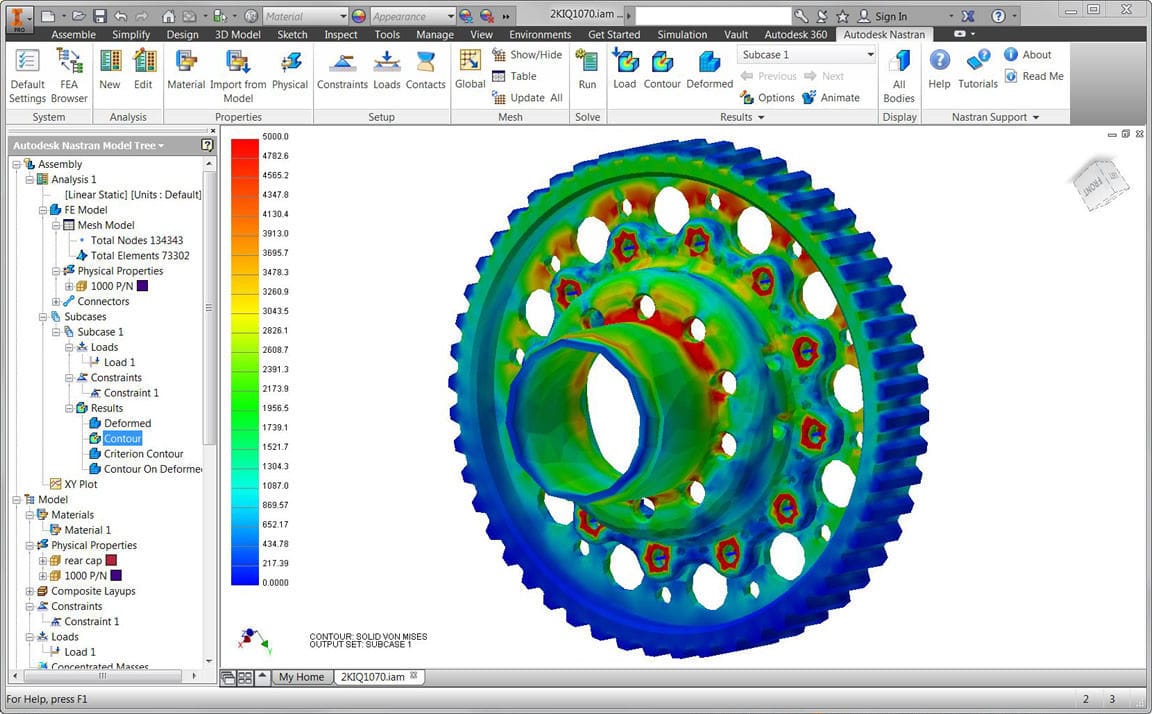

Integration into Nastran Model

After validation, you can integrate the data into your Nastran model:

- Assigning Temperatures: Use Nastran’s

TEMPDcard to assign temperatures to nodes or elements. - Applying Heat Loads: Use

QBDY1card or similar to apply heat loads or fluxes. - Setting Initial Conditions: If the model needs initial conditions, use Nastran’s

INITIALcard.

Final Checks and Run

Before running the analysis:

- Perform final checks for syntax and data format.

- Verify all required cards for thermal analysis are included.

- Submit the job to Nastran for analysis.

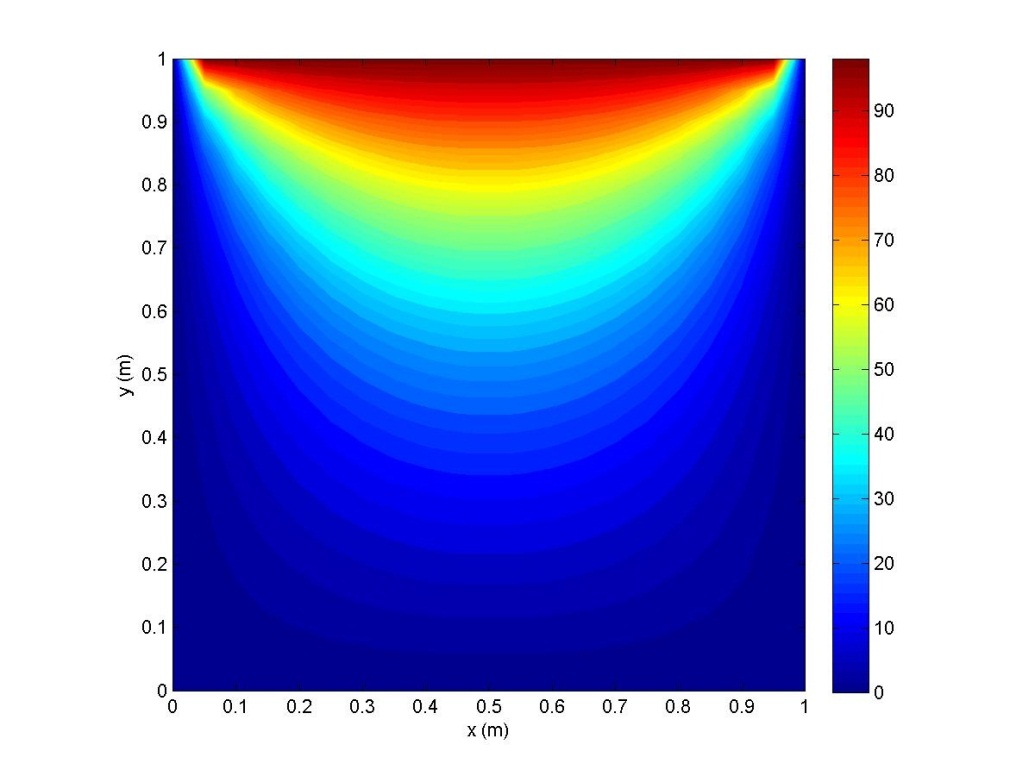

✅ Note: Utilize Nastran's post-processing capabilities for visualizing temperature distribution and verifying results against expected outcomes.

Best Practices and Tips

- Maintain a version control system for both your Excel spreadsheets and Nastran files.

- Automate as much as possible through scripting or tools to reduce manual errors.

- Document your process, including any assumptions or simplifications made.

- Verify results against expected or benchmark cases to ensure data integrity.

To wrap up, integrating Excel heat data into Nastran involves preparing data meticulously, choosing an appropriate conversion method, validating the imported data, and ensuring seamless integration into your Nastran model. Following these steps, you'll avoid common pitfalls, enhance efficiency, and achieve reliable results in your FEA thermal analysis. Remember, the key is in the preparation and validation stages, where careful attention to detail will save you time in the long run and lead to more accurate simulations.

What are the common formats used by Nastran?

+

Nastran uses Bulk Data Deck (BDF) or direct input formats like BDF, DMAP, DBALL.

How can I automate the conversion process?

+

Automation can be achieved with scripting languages like Python or through specialized tools like HyperMesh.

What to do if there are inconsistencies in the data?

+

Identify and correct inconsistencies by cross-referencing with initial data, using validation tools, or checking manually.

Can I use Nastran for thermal analysis?

+

Yes, Nastran has robust capabilities for thermal analysis, including steady-state and transient analyses.