Mastering Control Charts in Excel: Easy Guide

⚙️ Note: This guide is tailored for Microsoft Excel users. Versions from Excel 2013 onwards are recommended for the full feature experience.

Introduction to Control Charts

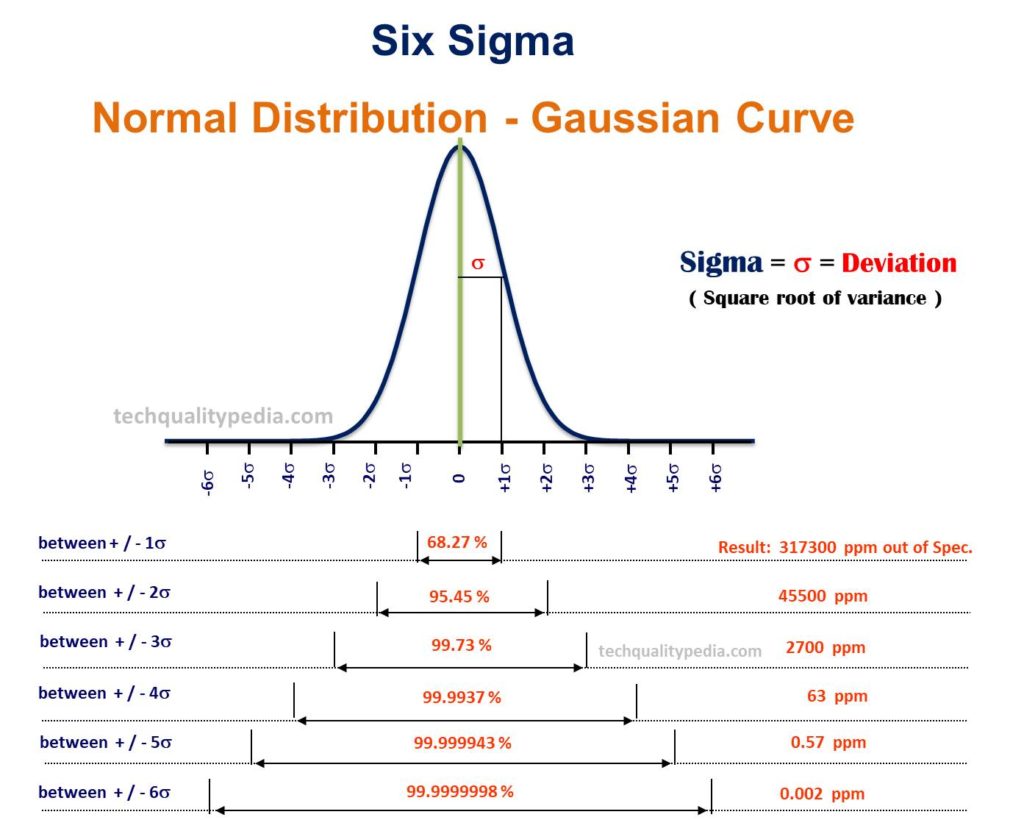

Control charts are fundamental tools in Six Sigma methodologies and quality control processes. They help in monitoring, controlling, and improving processes over time. By visualizing process variations, you can determine when a process is out of control or needs adjustment.

Setting Up Excel for Control Charts

Before diving into creating control charts, ensure your Excel software is up to date. Here’s a step-by-step guide to prepare Excel:

- Open Microsoft Excel.

- Go to File > Account > Update Options. Click Update Now to ensure all updates are installed.

- Enable Developer Tools by navigating to File > Options > Customize Ribbon, check the Developer checkbox, and then click OK.

- Explore Excel’s charting options by clicking Insert > Charts to familiarize yourself with available chart types.

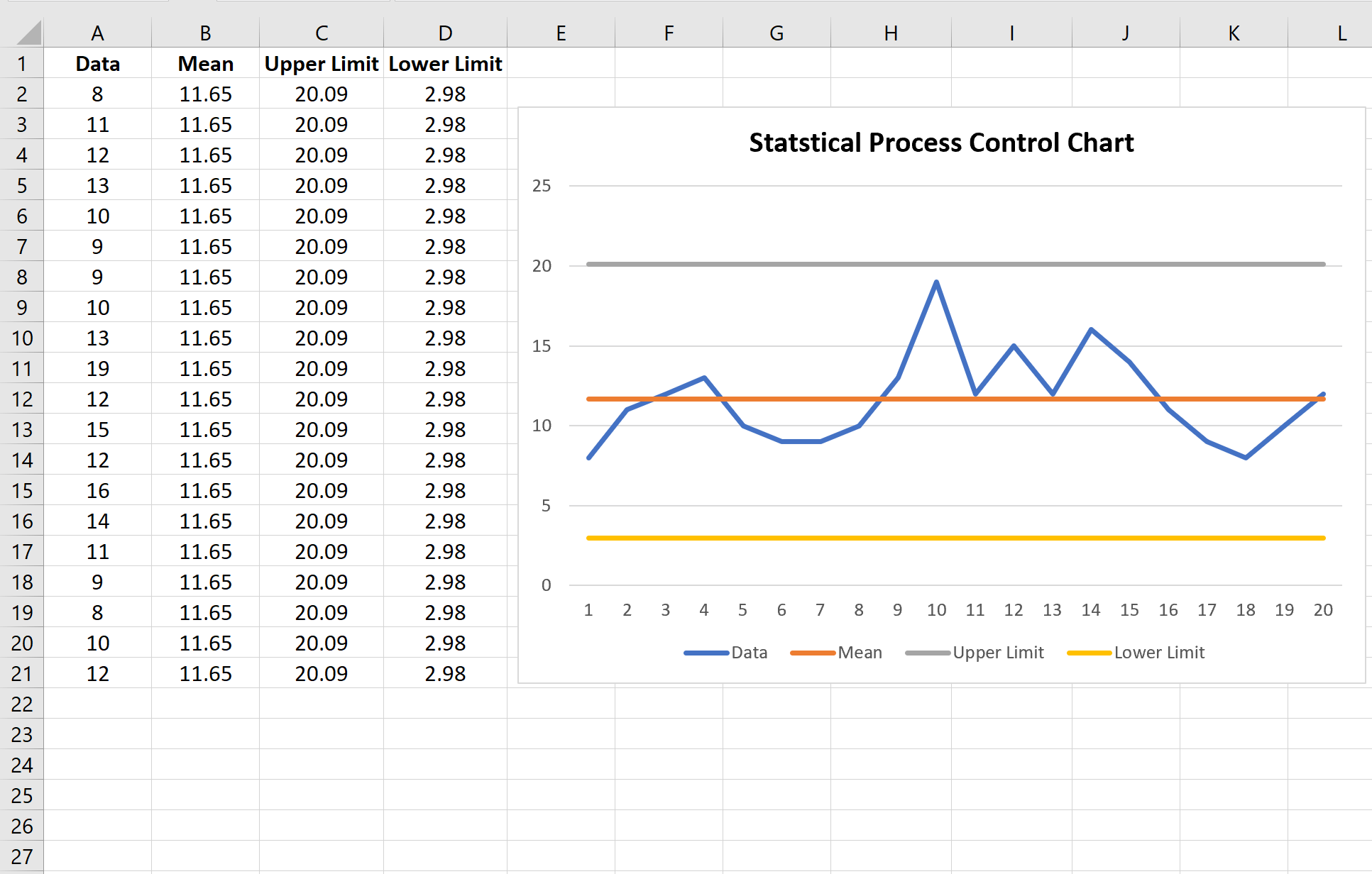

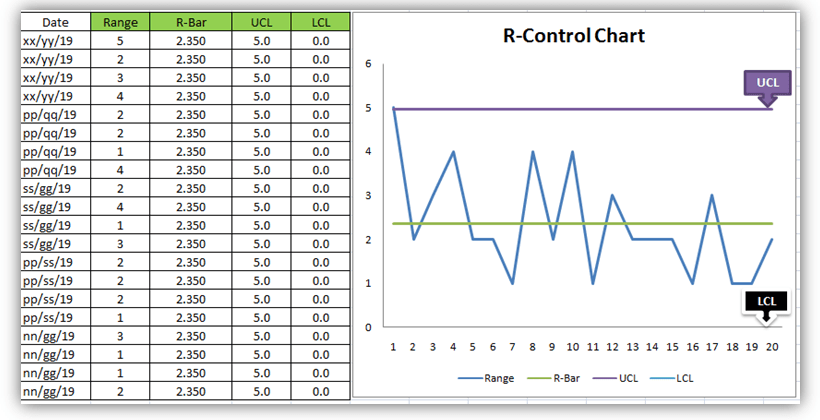

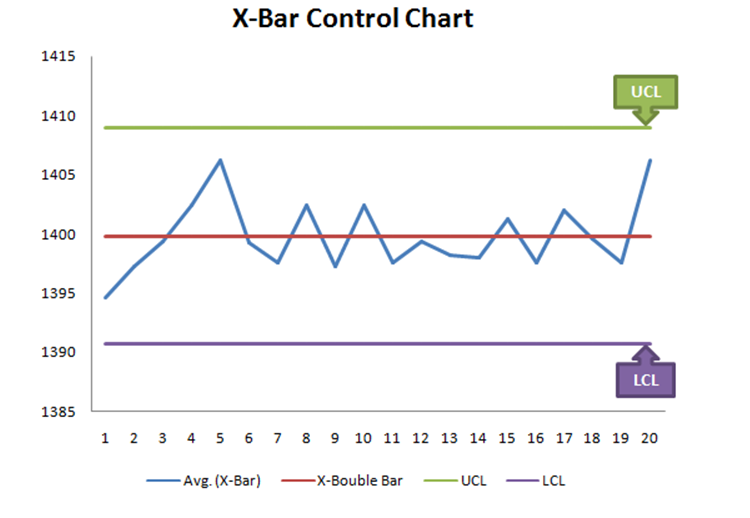

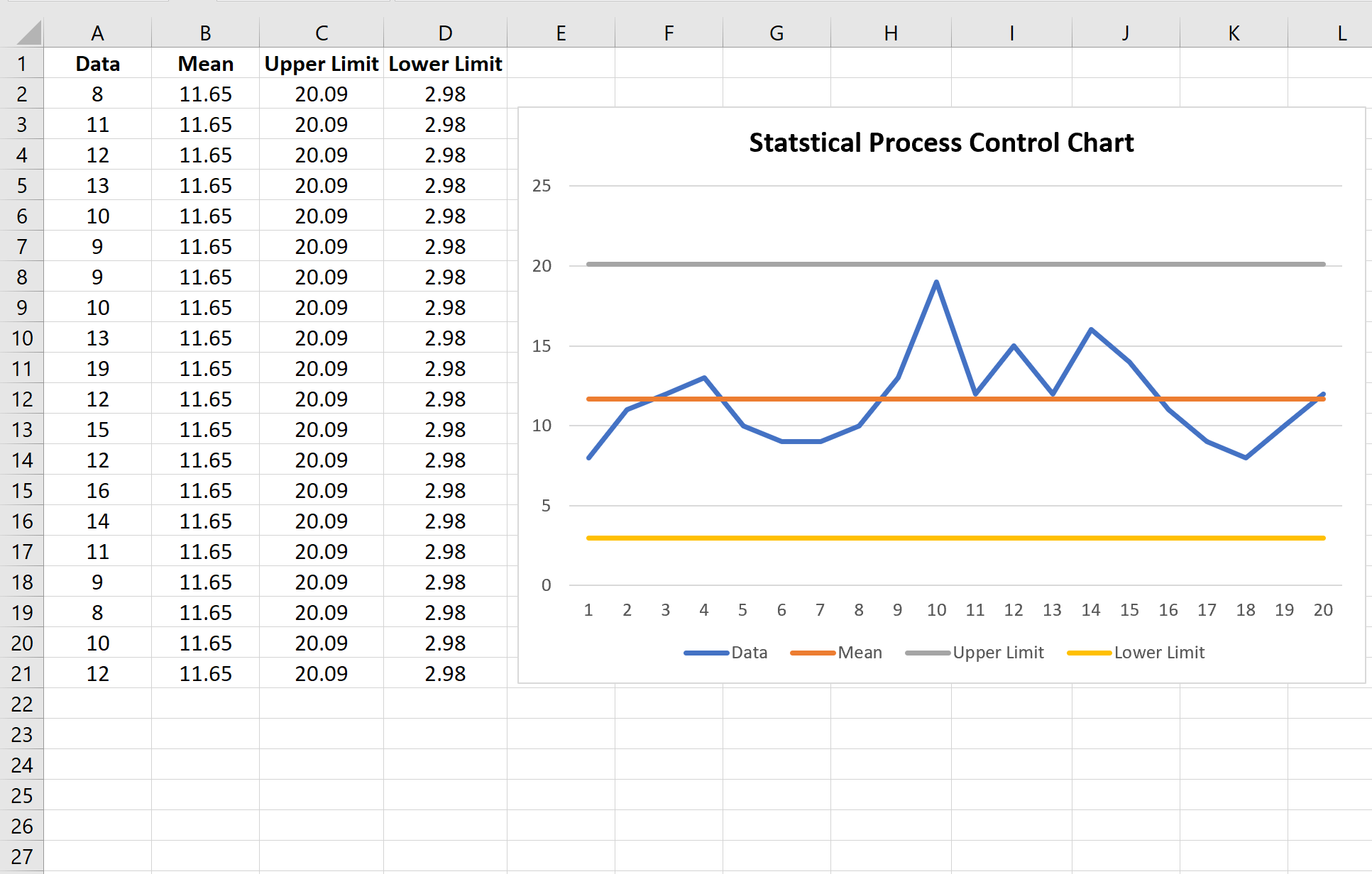

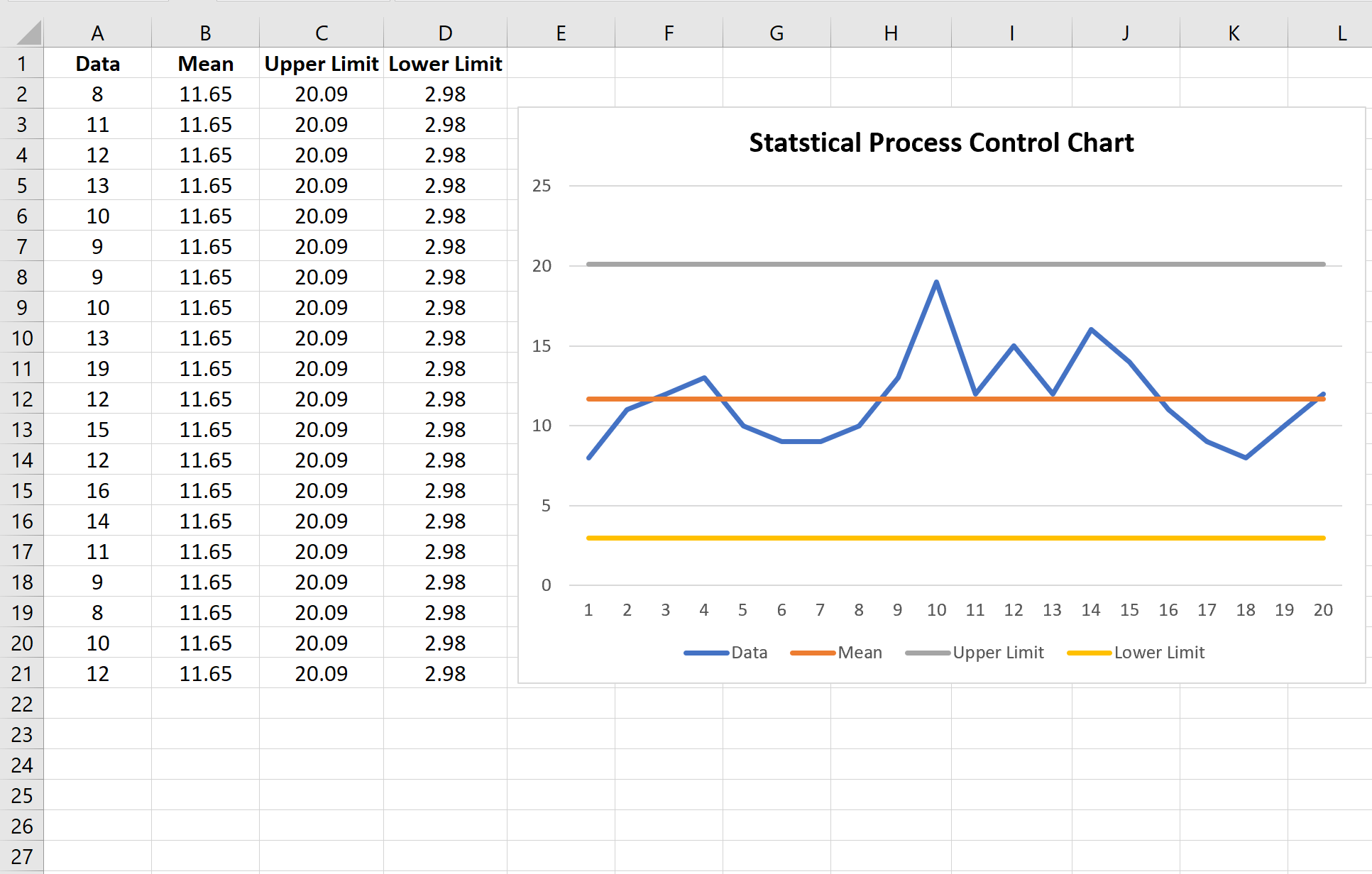

Creating a Basic Control Chart

Let’s create a basic control chart using a dataset of measurements from a manufacturing process:

Step 1: Enter Data

Input your data into Excel:

- Time/Observation in column A.

- Measured values in column B.

| Time | Value |

|---|---|

| 1 | 23.45 |

| 2 | 24.10 |

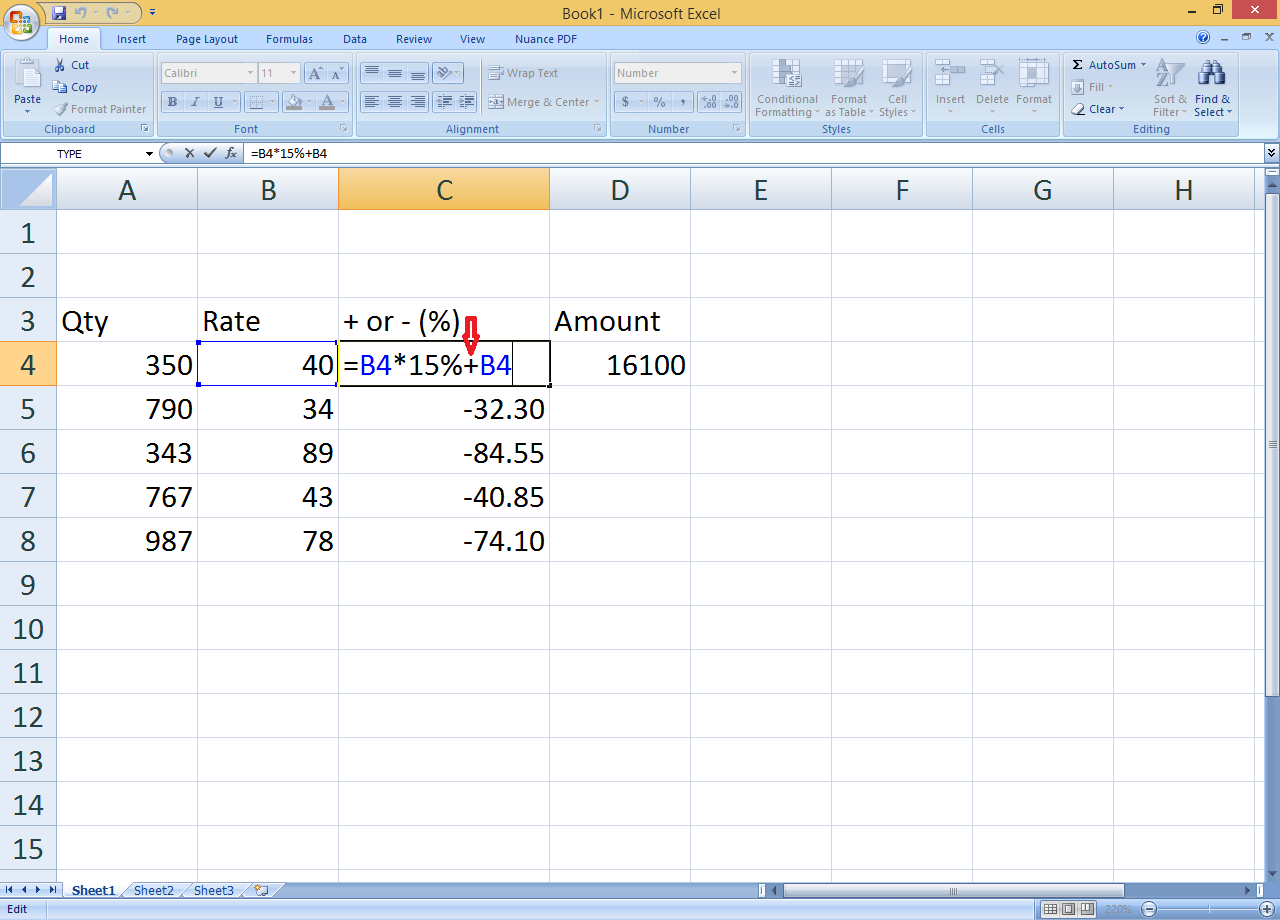

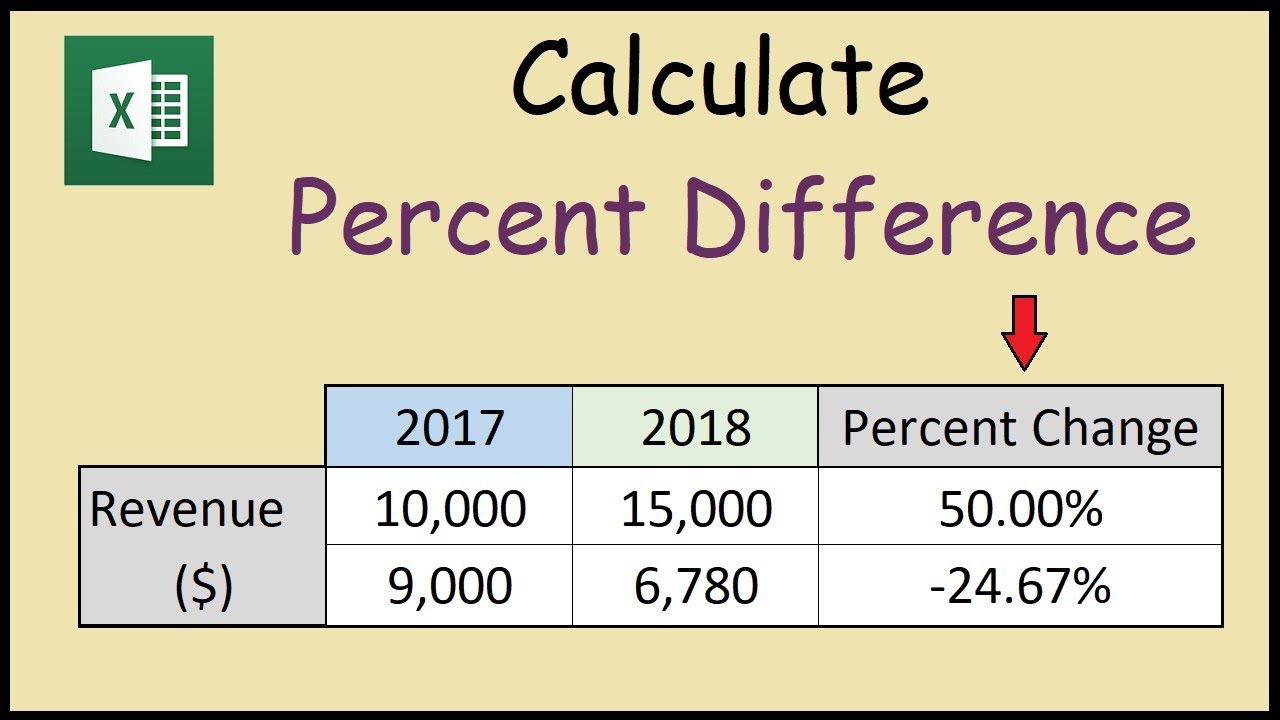

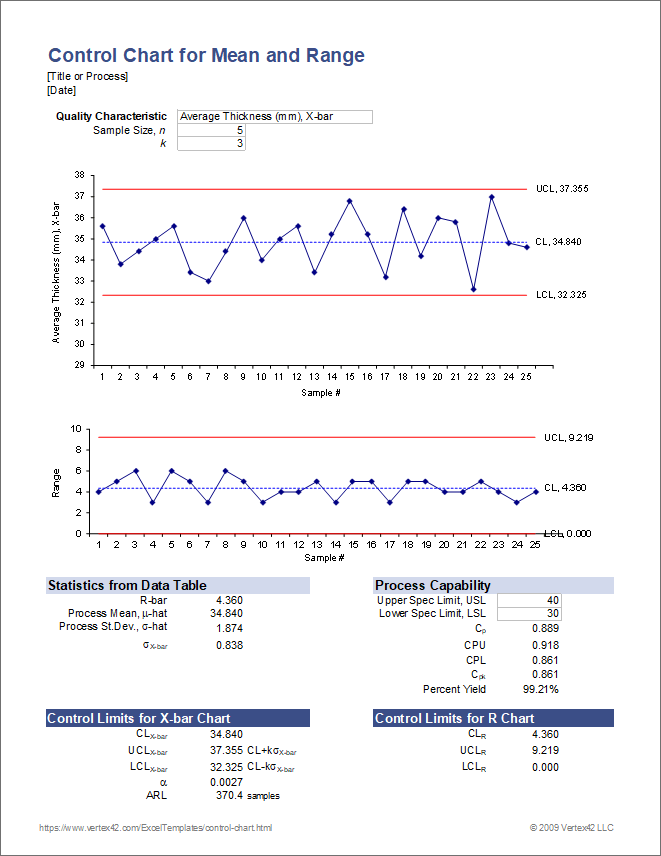

Step 2: Calculate Control Limits

You need the following calculations for a control chart:

- Mean:

=AVERAGE(B2:B200) - Standard Deviation:

=STDEV.S(B2:B200) - Upper Control Limit (UCL):

=Mean + (3 * Standard Deviation) - Lower Control Limit (LCL):

=Mean - (3 * Standard Deviation)

💡 Note: The '3' in the UCL and LCL calculations represents three standard deviations, which is a common rule in Six Sigma for defining control limits.

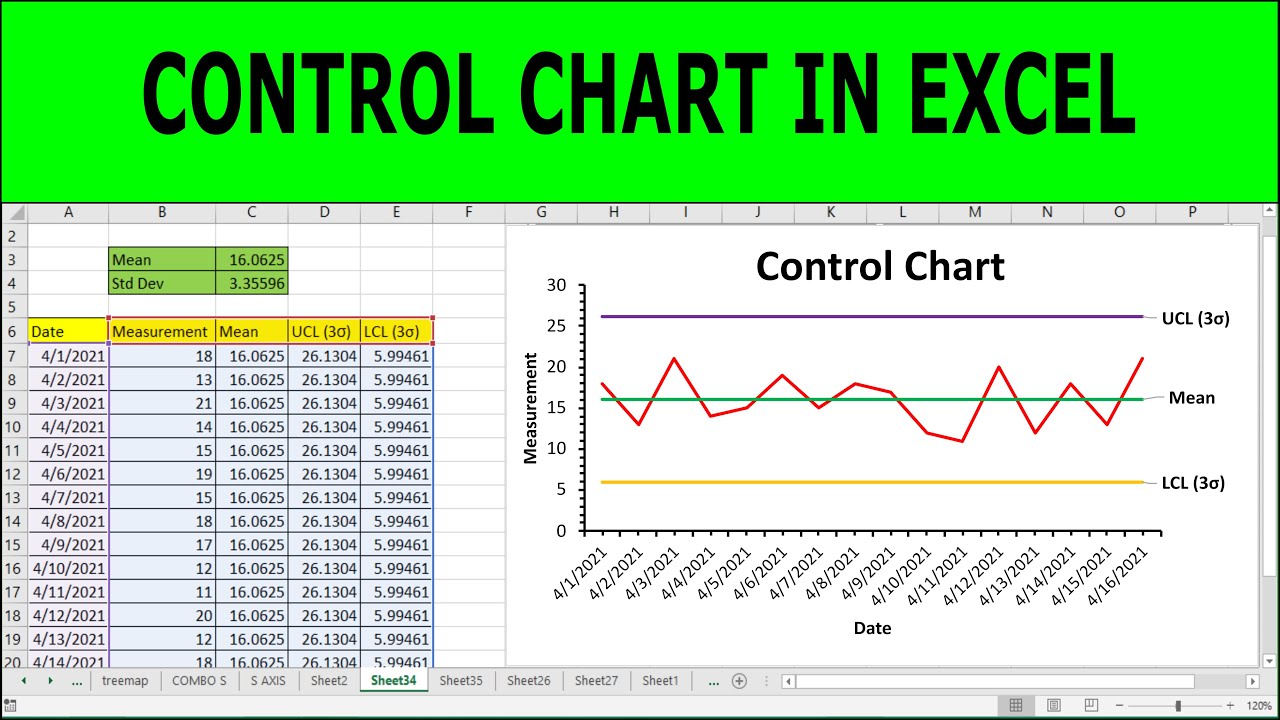

Step 3: Plotting the Data

Select your data range:

- Go to Insert > Chart.

- Choose Line Chart or Scatter Chart.

- Add the Mean Line, UCL, and LCL as new series.

=AVERAGE(B2:B200)will be used for the mean line, for example.

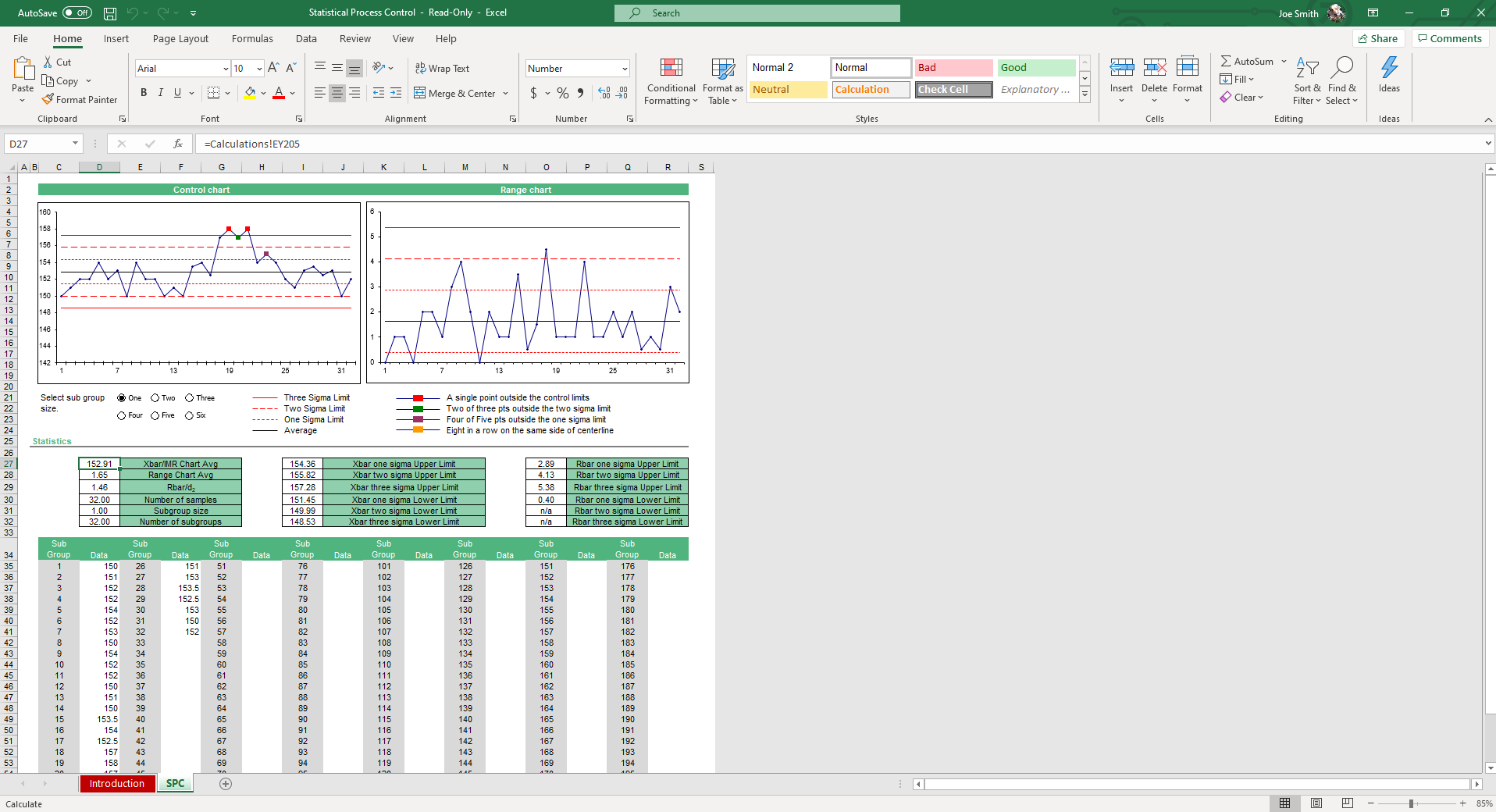

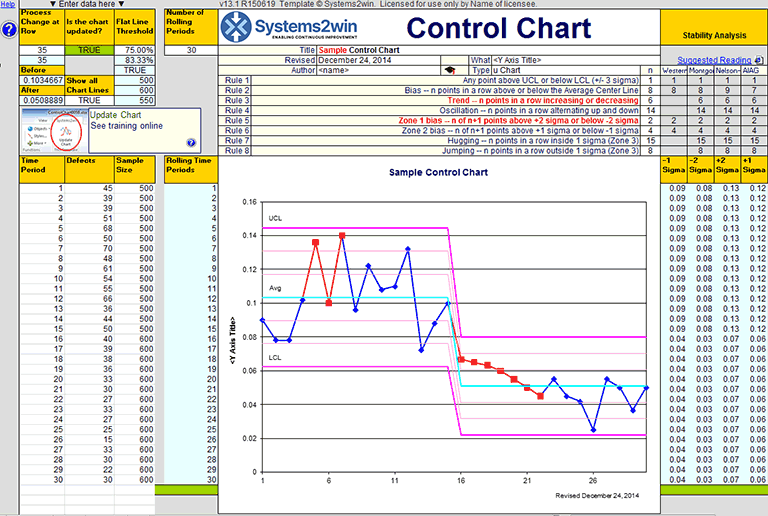

Advanced Customization of Control Charts

Here are some advanced features you might want to consider:

- Data Labels: Add labels to significant points or deviations.

- Custom Marker: Change markers for out-of-control points.

- Formatting: Adjust colors, line styles, and axis labels for better readability.

Interpreting Control Charts

Understanding what the chart indicates about your process:

- In Control: Points within the control limits suggest the process is stable.

- Out of Control: Look for:

- One point outside the control limits.

- Consistent trends in nine consecutive points.

- Other non-random patterns indicating process issues.

📈 Note: Regularly updating your control chart with new data allows for real-time monitoring and process improvement.

Wrapping Up Your Control Chart Mastery

Mastering control charts in Excel involves setting up your Excel environment, entering and analyzing your data, creating the chart, and interpreting the results. Each step requires careful attention to detail and a clear understanding of the Six Sigma principles to ensure that your processes are in control. With the steps provided, you can easily create and customize control charts to monitor your quality control efforts effectively. By using Excel’s powerful features, you can gain insights into your process variations, make data-driven decisions, and continuously improve your operations.

What are the benefits of using control charts in manufacturing?

+

Control charts help in tracking process performance over time, enabling early detection of issues, reducing variability, and improving product quality. They also provide a statistical basis for understanding process behavior, which aids in decision-making for process improvements.

Can control charts be used in non-manufacturing industries?

+

Absolutely! Control charts are useful in any industry where processes need to be monitored and controlled, including services like healthcare, finance, and IT, to name a few. They help in identifying process trends and out-of-control situations regardless of the sector.

What is the difference between a control chart and a run chart?

+

A run chart plots data over time but lacks control limits, while a control chart includes control limits to indicate when a process might be out of control. Thus, control charts provide a more comprehensive analysis of process stability.

How often should control charts be updated with new data?

+

Control charts should be updated as frequently as needed to reflect the current state of the process. This could be daily, weekly, or even in real-time if the data collection allows for it, ensuring that any process changes are captured timely.