5 Simple Steps to Create Control Charts in Excel

In the realm of statistical process control, control charts are powerful tools for monitoring processes and ensuring they run within specified control limits. Whether you're in manufacturing, quality control, or any field where performance metrics matter, understanding how to create and use control charts can help you identify variations and maintain process stability. This blog post will guide you through 5 simple steps to craft control charts using Microsoft Excel.

1. Gathering Data

The first step in creating a control chart is collecting data. Here’s how you do it:

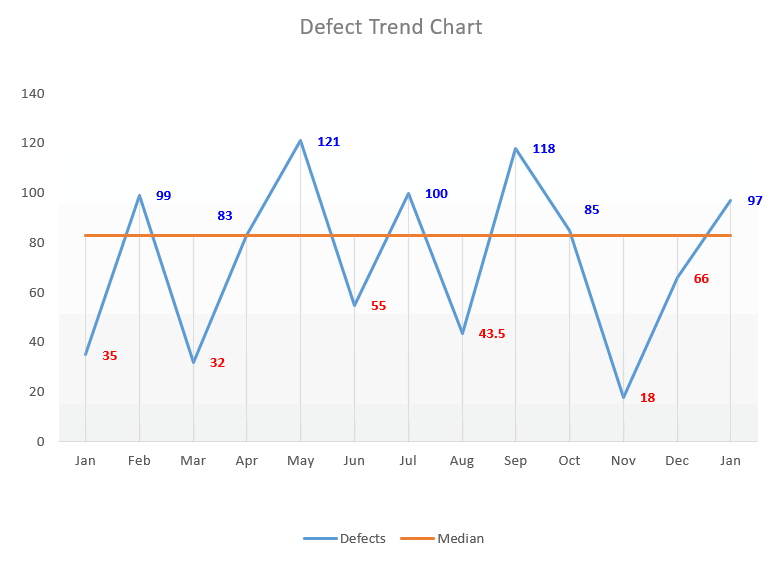

- Determine the Metric: Decide what variable or attribute you want to monitor. Common metrics include production times, defect counts, or test scores.

- Collect Sample Data: For control charts, you’ll need a series of measurements over time. Typically, you would collect 20 to 30 samples, each representing a subgroup from your process.

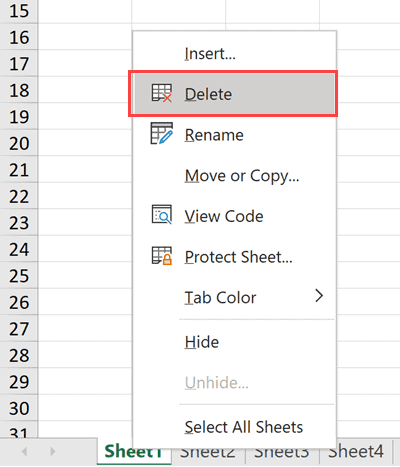

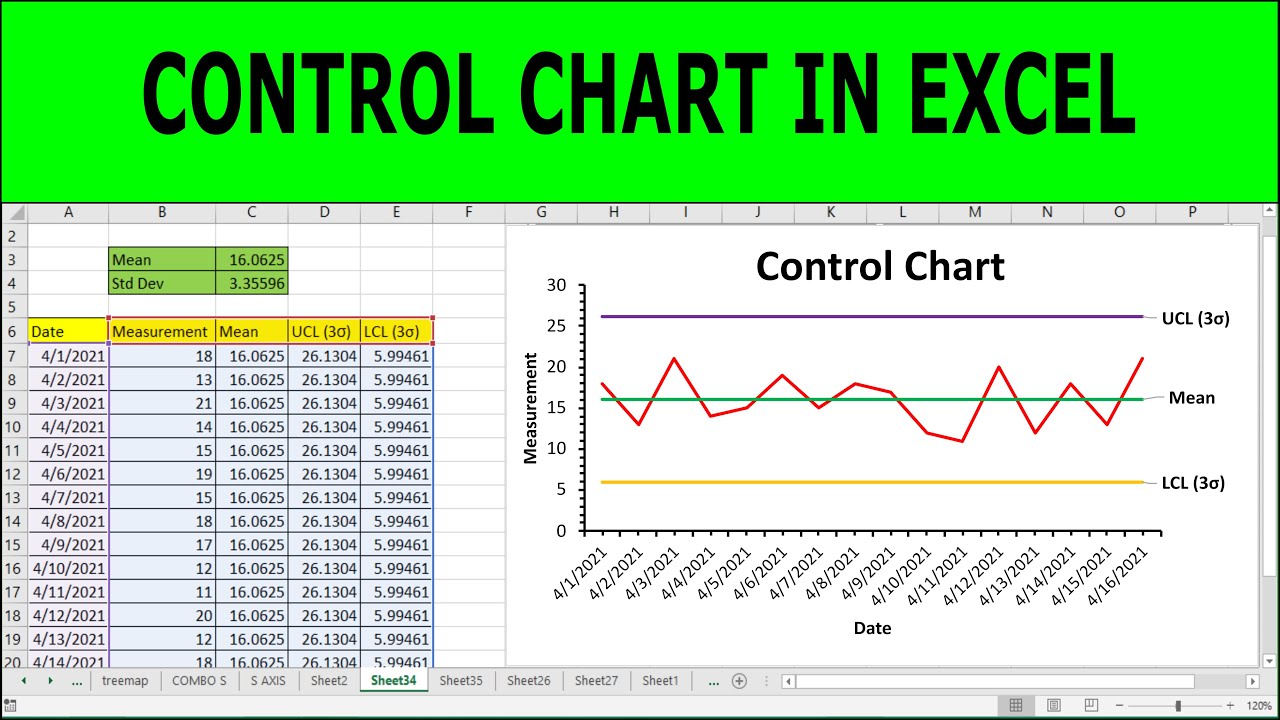

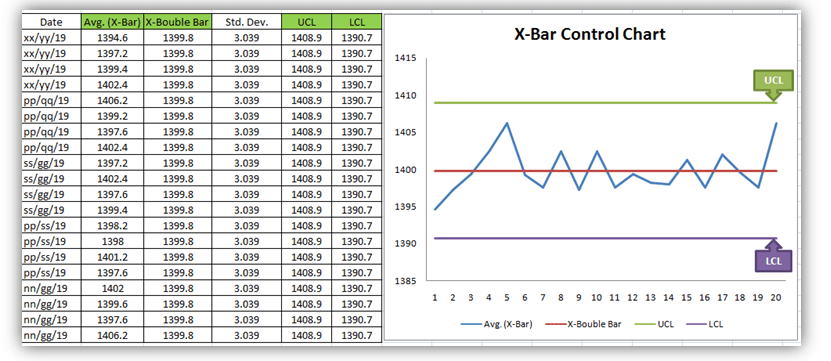

- Enter Data into Excel: Open Excel and enter your data into columns. Ensure you have:

- Time or subgroup identifier in one column.

- The measured values in another column.

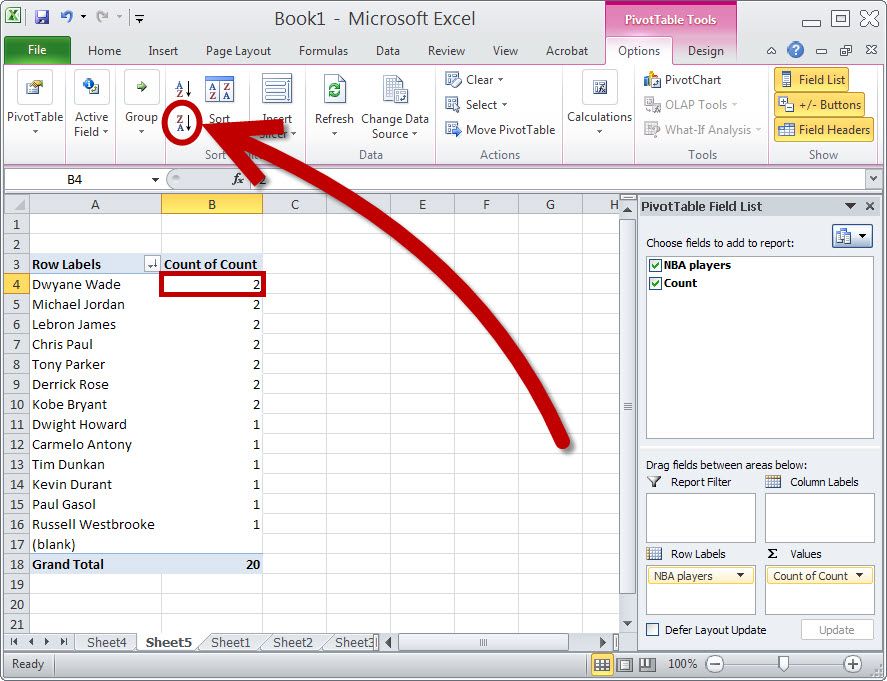

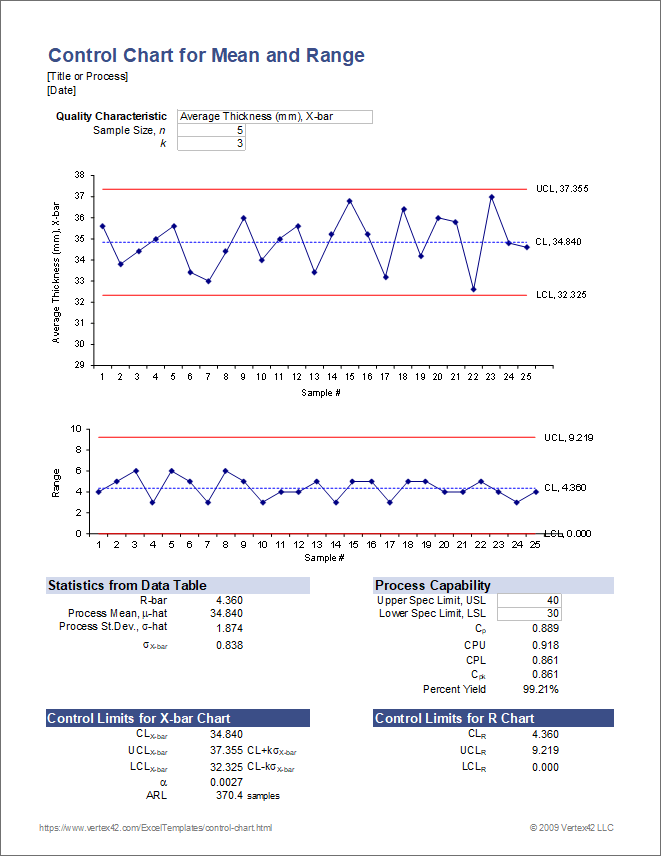

2. Calculating Basic Statistics

After gathering your data, you need to calculate several key statistics:

| Statistic | Formula |

|---|---|

| Mean (Average) | =AVERAGE(range of values) |

| Range (Highest-Lowest value in subgroup) | =MAX(range of values)-MIN(range of values) |

| Standard Deviation | =STDEV(range of values) |

Enter these formulas into Excel to calculate the mean, range, and standard deviation for each subgroup.

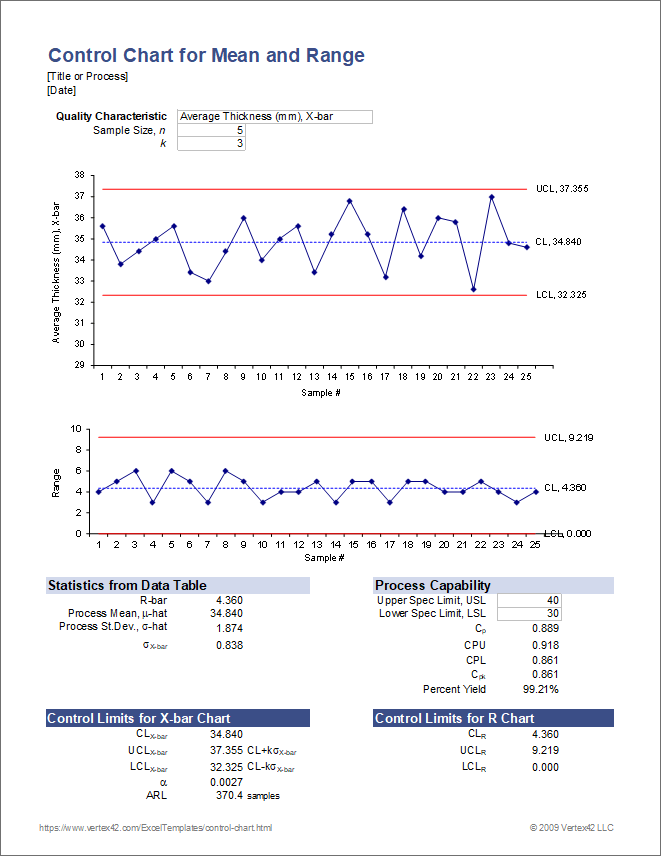

3. Setting Control Limits

Control limits are calculated to determine the thresholds within which the process is considered stable:

- Upper Control Limit (UCL): Mean + (3 x Standard Deviation/Control Charts Constants)

- Lower Control Limit (LCL): Mean - (3 x Standard Deviation/Control Charts Constants)

- Center Line (CL): The mean itself acts as the center line.

Control Charts Constants depend on the subgroup size:

| Subgroup Size | A2 | D3 | D4 |

|---|---|---|---|

| 2 | 1.880 | 0 | 3.267 |

| 3 | 1.023 | 0 | 2.575 |

| 4 | 0.729 | 0 | 2.282 |

📝 Note: When calculating control limits, ensure you use the appropriate constant from the table for your subgroup size.

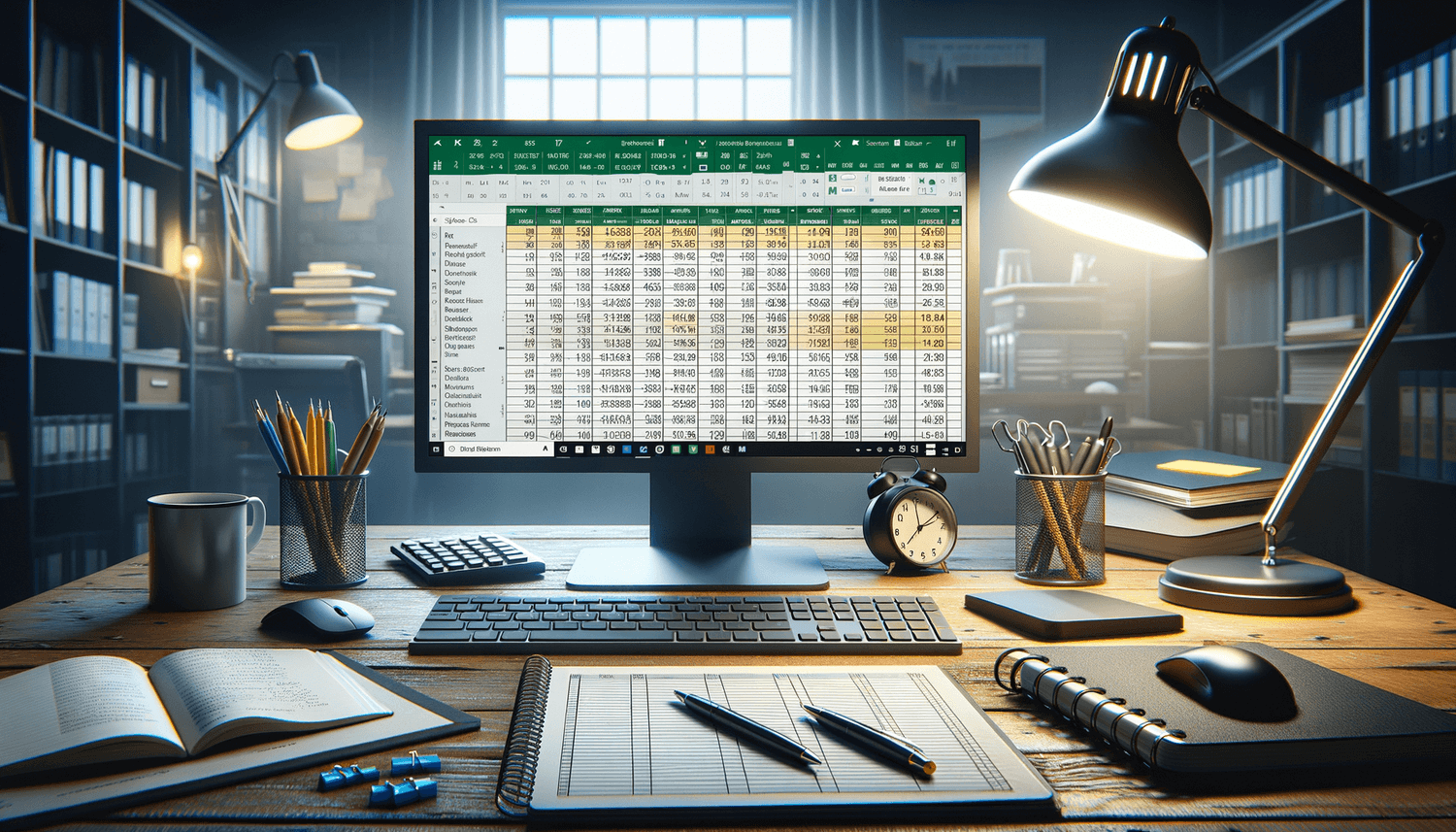

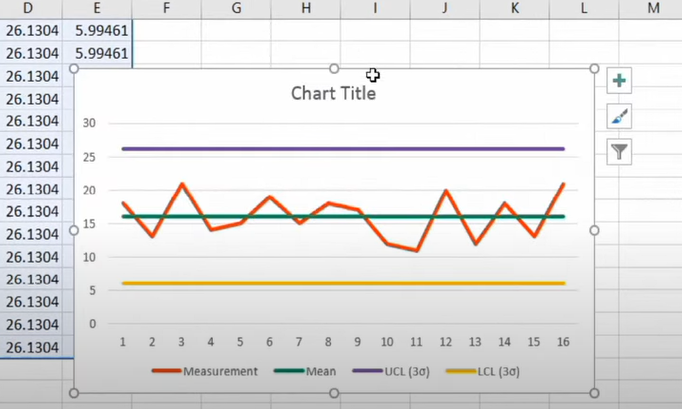

4. Plotting the Data

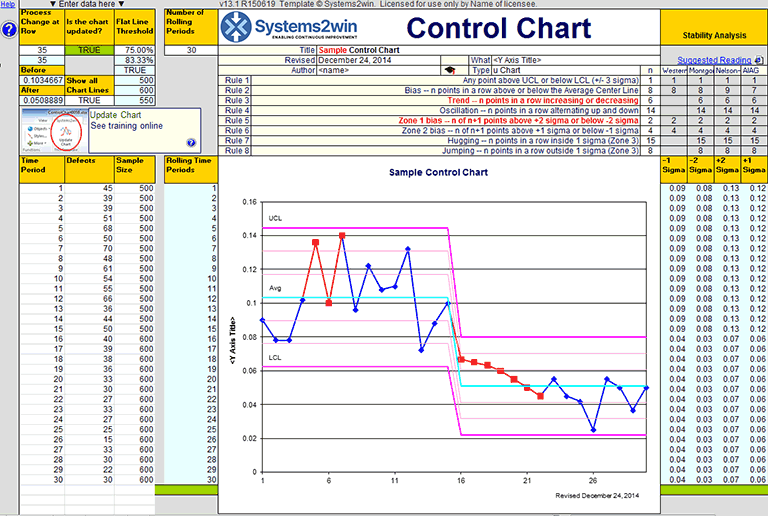

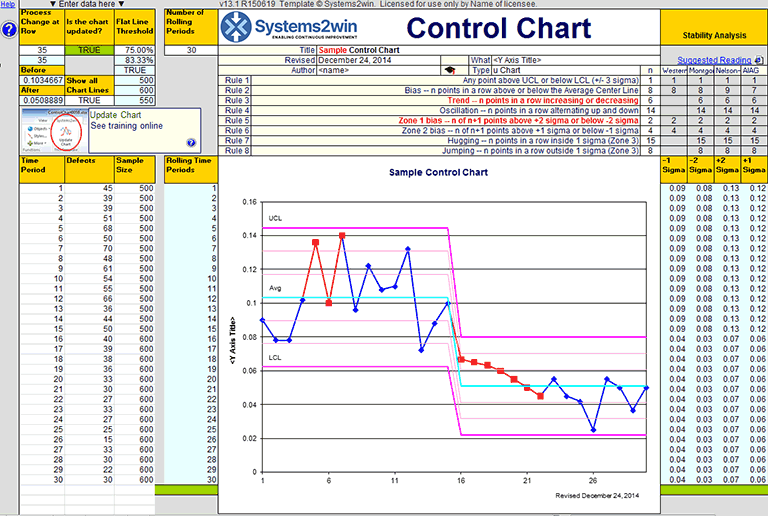

With your basic statistics and control limits calculated, now it’s time to visualize:

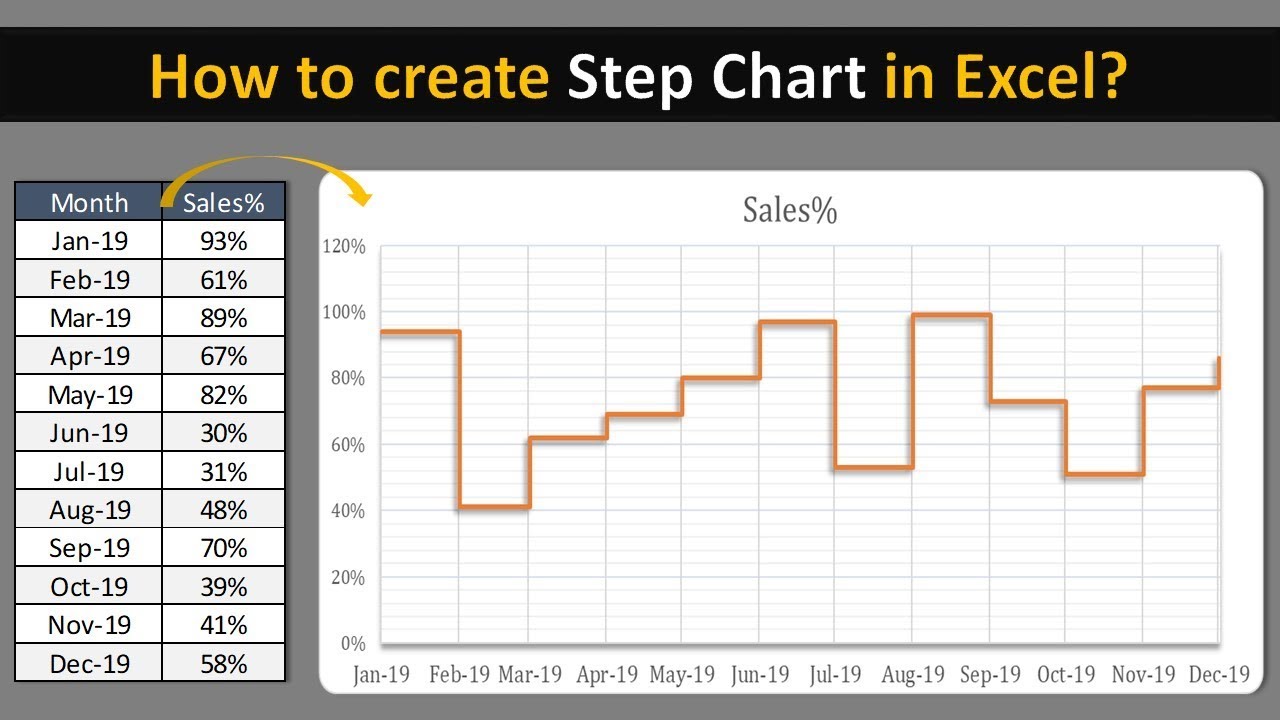

- Create a Line Chart: Select your subgroup data and use Excel’s line chart feature to plot it.

- Add Control Limits:

- Add a line for the CL, UCL, and LCL by using the “Add Series” option in the chart.

- Use “Error Bars” for the control limits to visually extend these lines across the chart.

- Format the Chart: Adjust colors, gridlines, and labels for clarity.

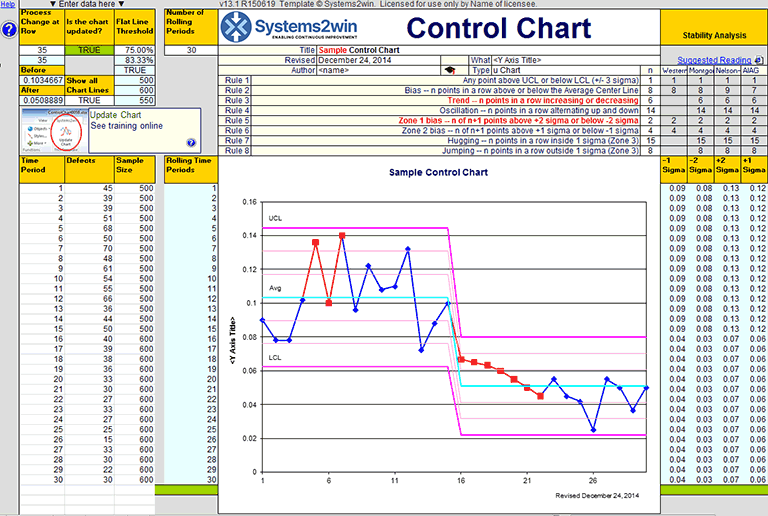

5. Interpreting the Control Chart

Once your chart is ready, you can now analyze it to draw insights:

- In-Control: All points fall within the control limits, and there are no patterns that indicate non-random variation.

- Out-of-Control: Look for:

- Points outside the control limits.

- Seven consecutive points above or below the centerline.

- Cyclic or trend patterns.

In summary, control charts in Excel allow you to keep track of your process's performance, ensuring it remains within acceptable parameters. From gathering data to interpreting the chart, this process provides valuable insights into process stability and can help identify when corrective actions are needed. Regular monitoring and analysis with control charts can significantly improve quality and efficiency in your operations.

What should I do if all points are within the control limits?

+

If all points are within the control limits, it means your process is stable and in control. You should continue monitoring to ensure it remains so, but there’s no immediate need for process adjustment.

Can I use control charts for non-manufacturing processes?

+

Absolutely. Control charts are versatile tools applicable to any process where output needs to be monitored for stability, including services, healthcare, education, and more.

What are the common mistakes when creating control charts?

+

Common mistakes include:

- Using too few data points for meaningful analysis.

- Setting inappropriate control limits.

- Overlooking natural process variations, leading to unnecessary adjustments.

- Ignoring trends or patterns that are statistically significant.

How often should I update my control chart?

+

The frequency depends on your process. For high-volume manufacturing, daily updates might be necessary. For others, weekly or monthly updates could be sufficient. It should be frequent enough to catch variations in time.